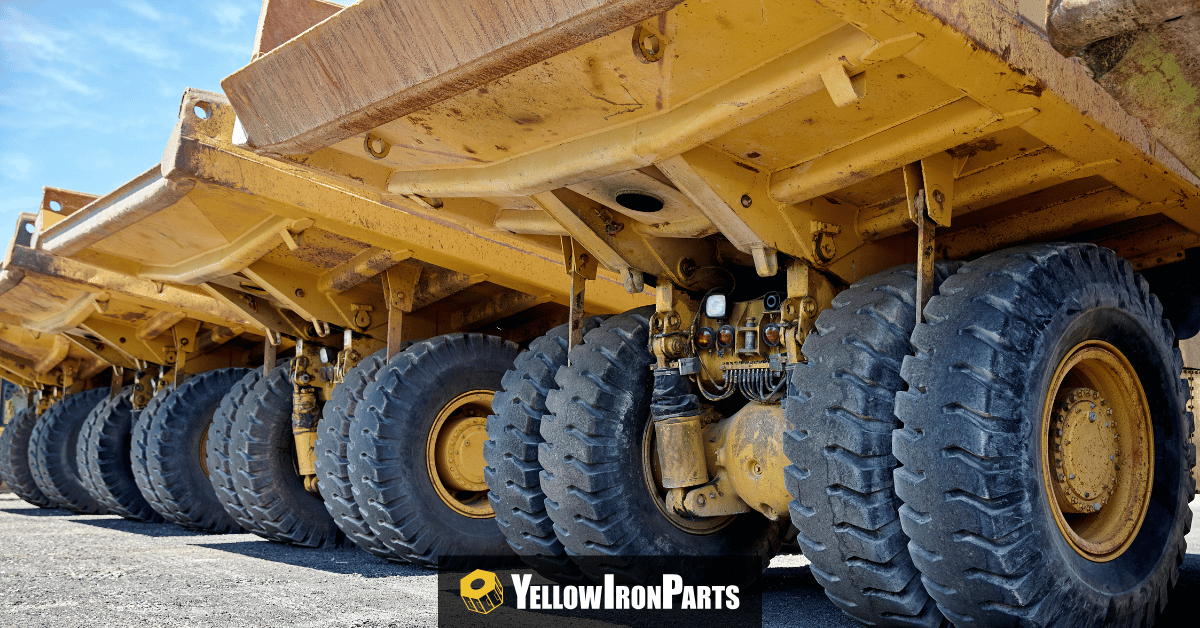

Choosing the right equipment impacts your bottom line. ROI, or return on investment, helps determine the long-term value of a machine. Smart equipment decisions can improve project efficiency, reduce costs, and increase profits. Understanding how to evaluate ROI allows contractors and fleet managers to invest with confidence.

What ROI Means in the Heavy Equipment Industry

ROI measures how much profit a machine generates compared to its cost. It’s a key performance indicator for any equipment investment. A higher return on investment means the machine delivers strong value over time.

Many contractors focus only on purchase price. True ROI considers ongoing costs, downtime, and eventual resale value. To calculate, use this simple formula:(Net Profit / Equipment Cost) x 100

Key Factors

- Resale Value – Equipment that holds its value brings a better return when you sell or trade it in.

- Initial Cost – Consider whether you’re buying new, buying used, or renting.

- Maintenance and Repair Expenses – Frequent breakdowns lower ROI and increase long-term costs.

- Fuel Efficiency and Operating Costs – Machines that burn less fuel while maintaining performance improve profitability.

- Downtime – Equipment that sits idle or breaks down delays projects and reduces overall ROI.

How to Calculate ROI Before Buying or Renting

Before making a purchase, estimate the machine’s lifetime cost and expected earnings. For example, an excavator might cost $120,000 and earn $15,000 per month. If it works for 24 months and costs $10,000 in maintenance, your ROI would be 140%. ([(15,000 x 24) – (120,000 + 10,000)] / 130,000) x 100 = 140%.

You can use similar calculations for any machine. Always compare models, fuel usage, and service histories.

Smart Parts and Equipment Decisions

Every repair and replacement decision affects your ROI. Choosing high-quality parts reduces downtime and extends equipment life. Preventive maintenance also protects your investment and avoids major breakdowns. Aftermarket parts and attachments can increase your machine’s versatility and usage.

YellowIronParts offers a wide selection of new and used parts from trusted vendors across the United States.

Fleet Management Strategies

- Rotate or sell underperforming machines and reinvest in higher-return assets.

- Track ROI across the entire equipment lineup.

- Assign equipment to the right jobs for full utilization.

- Avoid letting machines sit idle for long periods.

- Use digital tracking tools to monitor usage, maintenance, and costs.

- Evaluate which equipment delivers the most value for each project type.

The Center of Every Equipment Decision

Every equipment purchase should focus on ROI. Machines that perform well, require less maintenance, and hold value bring the greatest return. Whether you’re buying, renting, or maintaining a machine, ROI should guide your decisions. High-performing machines start with smart parts and reliable service. You can shop both on YellowIronParts.